Hello Bala. 1st thing we need to do is make sure you are jumping the correct connector. On your van the "Check Engine Connector" is among a group of 3 dead-end terminals right behind the air flow meter. It's the medium sized one and the only one with 2 wires going to it. One wire is brown and the other is gray with a black stripe. Here are some pictures of the "check engine connector":

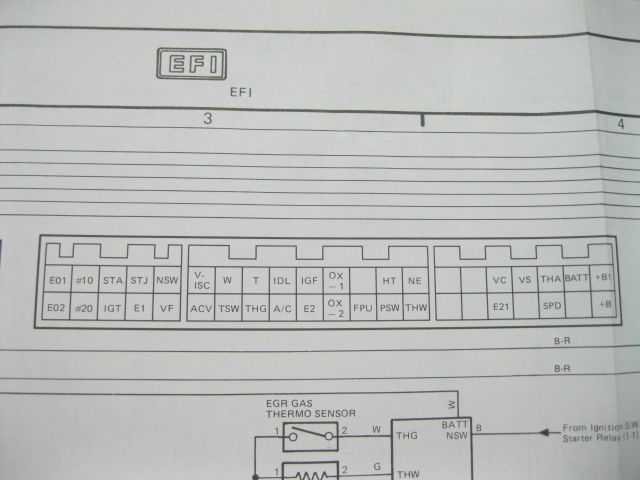

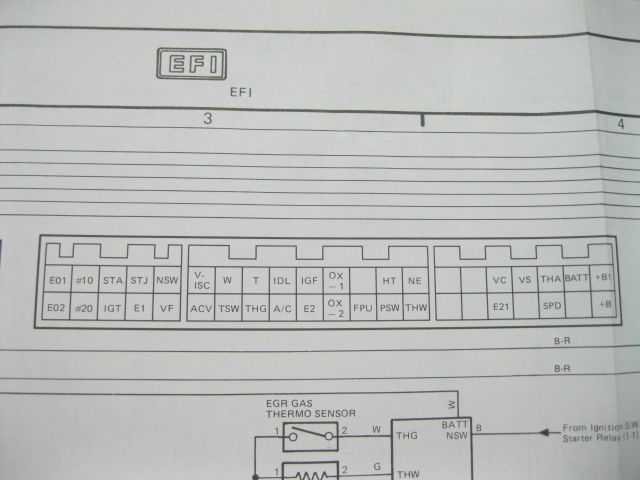

If nothing happens when you jump those wires (no check engine light and no change in idle), and the connector is in good shape, then this indicates a problem with the ECU or the Check Engine circuit somewhere in the harness. You could try swapping ECUs (if you happen to have an extra one laying around) or you could test the harness with an ohm meter at the ECU connectors. Since you probably don't have an extra ECU, then you'll need to gain access to your ECU (mounted in the D/S pillar behind where your seat belt retracts to), and unplug the harness. Now you can test for continuity between positions "T" and "E1" in the harness. Here is a map of the ECU connections:

With the "check engine connector" empty there should be no continuity. With it jumped there should be. If the harness tests okay, then the problem is in your ECU. If you are not getting continuity between these 2 pins with the jumper in, then your problem is in the harness. If this is the case, your choice would be to find the fault and repair the harness or you could cut some insulation off these two wires at the ECU and touch them together. Touching them together at the ECU will have the same effect as jumping the engine connector, but would be somewhat of a "hack" thing to do. If you go this route, just be sure to tape them up when you're done.

If none of this works, tell me what you did, what you found, and we'll move on to a couple other things you can try. Tim

PS: When you changed the TPS did you adjust it per specs using an ohm meter?

Reply With Quote

Reply With Quote