-

Re: Alternator woes

Hello and welcome to the site! FWIW, it's okay to mention www.toyotavanpeople.com here. I assure you the censorship between them and us is a one way street. I guess what works best for you will depend on your mechanical ability, your willingness to get your hands dirty, and your resources.

In my opinion a damaged but original alternator is better than a working rebuilt one (the exception being an alternator rebuilt by Denso). The original alternators can usually be repaired for a fraction of the cost and will typically last longer than the "lifetime" rebuilds you find at the auto parts houses. If however you need something fast and don't have the ability to repair then a rebuilt one might work better for you. If you go the rebuilt/remanufactured route, I would just pay the core charge and save your original (perhaps you could fix it later and keep it as a spare).

I understand the challenge of repair without the correct equipment. Unless you have a bench tester all you can do is disassemble, clean, perform a visual inspection, repair/replace as required (any obvious defects), and re-assemble. Once you think you got it fixed you can take it to an auto electric business for testing on a machine. Most auto parts houses also have the bench testing machines, but finding a sales guy competent enough to run it might be a problem. Some of your more reputable places like Napa have better trained counter guys and you'd have a better chance there.

Before I got my bench tester that's how I did it. It's hardly worth making an investment like that for a single alternator repair, so taking it in for testing is probably the way to go. I got my tester because over a 10 year period I had collected 8 failed alternators  . After repairing them I sold them for $40 each, so that helped pay for the machine (it's really more of a toy for me).

. After repairing them I sold them for $40 each, so that helped pay for the machine (it's really more of a toy for me).

Based on what you said I'm guessing it's just your brushes that have failed and the rest of the alternator could be fine. Brushes that fail due to power steering leaks are usually pretty obvious so I'd at least take the tin cover off the case and check those before going and replacing the entire thing. Whatever you decide, by all means repair the power steering leaks before putting an alternator back in there. For information on the common power steering pump leaks CLICK HERE.

As for alternator removal here are a couple of good threads where this is discussed:

https://www.toyotavantech.com/forum/...or-ILLUSTRATED!

https://www.toyotavantech.com/forum/...atively-easily....

Once your alternator is removed inspect the harness and replace if questionable. The round harness that plugs into the back of the alternator (with 3 small wires going to it) tends to get broken wires in it. Often times the wires will look good on the outside but the conductors inside can be compromised. CLICK HERE for more information on the alternator harness.

Once out it's fairly easy to disassemble the alternator. Here are some pictures of what you can expect to find:

These are your alternator brushes

These are your brushes on ATF (power steering fluid)

Alternator brushes are Toyota Part #27370-35060 and sell for about $15 - $30 (depending on the dealer). Another thing to check (2nd most common failure) is the diode assembly. Here is a messed up one off of a remanufactured alternator:

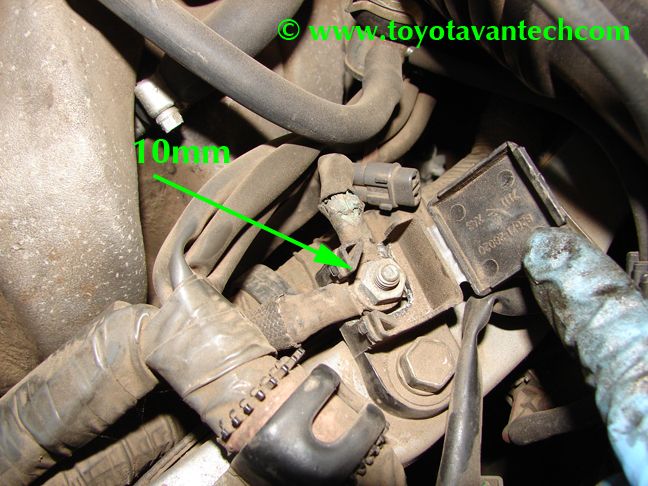

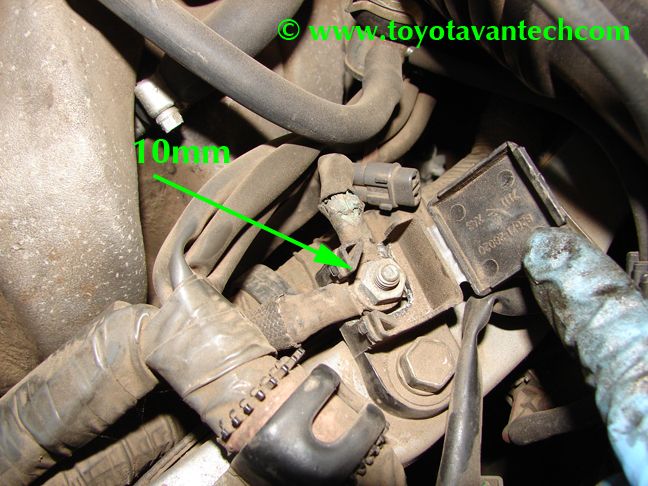

If you look closely you can see several of the diode stems have desoldered themselves from the assembly. This is partly due to a low temp solder the rebuilder improperly used and partly due to the alternator being overworked (owner tried to use it to recharge a dead battery). I don't have a factory Denso diode assembly handy for pictures, but those are identifiable by a gray plastic coating Denso uses to protect from moisture. Even if your diode assembly looks good it doesn't mean it is. There are several diodes here but it only takes one to fail and you're dead in the water. Sometimes diodes short. A shorted diode will allow electricity to travel both ways. An alternator with a shorted diode will often still charge okay but will also discharge when not in use. The easiest way to test for this is before you remove the alternator. Go to the little plastic "+" box (under & slightly forward of your air intake tube) & open it up.

Being careful not to touch your tools on any other metal surfaces remove the 10mm nut from the stud. Now remove the eye terminals from the post & touch them together. If they spark or arc, then you have a shorted diode and the diode assembly will need to be replaced. Protect these wires from touching any metal surfaces & before going any further disconnect the battery! Removing the alternator with the battery still connected can be very exciting  .

.

Even if the diode assembly passes the above test and it looks good, it could still have an "open" diode. An open diode is one that will not conduct electricity in either direction. Testing for an open diode is easy IF at least one side of the diode is disconnected. Unfortunately since these are soldered with a high temp solder disconnecting them for testing is not an option. The only way I know how to test for this is to put the diode assembly into an otherwise good alternator and run a bench test on it. If the output voltage is low or not even there then the diode assembly is bad and should be replaced. I haven't priced diode assemblies, but frankly I wouldn't want a remanufactured one and I probably couldn't afford a new Denso one. For this reason I shop for them at the pick & pull salvage yards. It's actually pretty easy and inexpensive to find good Denso diode assemblies at the yard. Keep in mind that Denso made variations of this same alternator for many vehicles. There are many vehicles from this era that use internally identical alternators. The cases and mount configurations are often different but the internals are the same. This is good news because it gives you several vehicles to choose from. I've found several Toyotas and several Hondas (among others) to be 100% compatible (other than the cases). Just look at the connection locations on the back side and make sure the round regulator plug is a match.

Another big advantage to this is these alternators are usually in good shape. Even if they have a bunch of miles on them they have most likely had a relatively easy life (cool environment and no ATF leaking onto them). I've pulled several apart with over 200k miles on them and found them to be original equipment and only in need of brushes. Another awesome thing is ease of removal. I always look for the transverse mounted engines that have the alternators mounted on the front side of the engine. These can be removed in just a few minutes. Most pick & pulls around here will charge $19.95 for the complete alternator, but I've found they will usually sell me the diode assembly for about $5. They will often just give them to me for free if I'm making a bigger purchase  .

.

Voltage regulators are the 3rd most failed component on these alternators. Here is a picture of one (left side of picture sitting on box):

Like the diode assemblies, the only way I know to test these is by putting into an otherwise good alternator and running it on the bench tester. I've purchased these new from www.rockauto.com for around $20 on their close-out sales (Standard part#VR-405), but I actually feel a bit more comfortable with the used Denso ones from the pick & pulls. Again, they will usually charge me anywhere from $0 - $5 each.

There are other parts inside the alternator that can fail, but these are the 3 big ones. It's been my experience that bearings, windings, etc will often go beyond 300k miles so why compromise reliability by replacing with a remanufactured unit? Here's a little video I made while playing with my alternator tester. Enjoy  Tim

Tim

Tags for this Thread

Posting Permissions

Posting Permissions

- You may not post new threads

- You may not post replies

- You may not post attachments

- You may not edit your posts

-

Forum Rules

. After repairing them I sold them for $40 each, so that helped pay for the machine (it's really more of a toy for me).

.

.

Tim

Reply With Quote

Reply With Quote